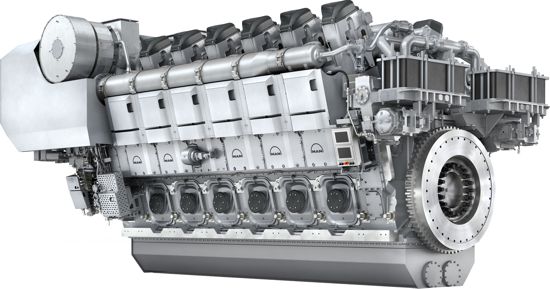

In the early days, diesel engines were only used in agricultural machinery, tractors, etc. Modern diesel engines generally use technologies such as electronically controlled injection, common rail, turbocharging, and intercooling, which have made major breakthroughs in weight, noise, smoke, and have reached the level of gasoline engines. Today’s diesel generators can not only meet the relevant laws and regulations and the increasingly stringent international standards in terms of emissions and noise, but it can also be widely used in marine, agricultural, engineering machinery, and other fields.

How Does a Diesel Engine Work?

The diesel engine sucks pure air in the intake stroke. When the compression stroke is near the end, the diesel oil is increased by the fuel injection pump to more than 10MPa and injected into the cylinder through the fuel injector, and the compressed high-temperature air in a short time Mix to form a combustible gas mixture. Due to the high compression ratio of the diesel engine (generally 16-22), the air pressure in the cylinder can reach 3.5-4.5MPa at the end of compression, and the temperature can reach 750-1000K, which greatly exceeds the auto-ignition temperature of diesel. Therefore, after being injected into the cylinder, diesel fuel will be combusted immediately after mixing with air in a short time. At this time, the air pressure in the cylinder rose rapidly to 6-9MPa, and the temperature also rose to 2000-2500K. Driven by high-pressure gas, the piston moves downward and drives the crankshaft to work.

What are the advantages of diesel engines compared to engines operating on other principles?

First, diesel engines have the highest effective efficiency of combustion engines. The diesel engine injects fuel directly into the combustion chamber. Except for the air filter and intake duct, there is no intake restriction, and there is no intake manifold vacuum to increase the parasitic load, and because the piston is in the direction of the intake system vacuum Pulldown, thus causing pumping loss. For the same reason, it can help the cylinder fill the atmosphere and improve volumetric efficiency. Although the fuel efficiency of a diesel engine will decrease at lower loads, the rate of decline will not be as fast as typical gasoline or turbo engine.

In addition, compared with gasoline engines that have a larger market share, diesel generators have the following advantages:

- Low fuel costs, as fuel oils are relatively cheap

- Good lubrication properties

- High energy density

- Low risk of catching fire, as they do not form a flammable vapor

These benefits explain why diesel engines are widely used in large-scale diesel equipment, including transportation, engineering machinery, agricultural machinery, marine power, railway diesel locomotives, generator equipment, defense equipment, and other various general machinery have applications. Although diesel engines are heavy, noisy, and emit soot, they are rarely used in the field of passenger cars. However, after continuous accumulation and breakthroughs in technology, modern diesel engine technology has improved its shortcomings. Diesel engines have obvious advantages in energy saving and carbon dioxide emissions, and they have a greater advantage in non-road applications. In the field of roads, as the demand for engines in commercial vehicles, especially heavy truck markets, gradually develops toward high horsepower and high-end, diesel engine market, the diesel engine market still has good development prospects in the future.